- ♨️【EXCEPTIONAL PERFORMANCE】There are three rows of 3/8″ copper tubes and 12 aluminium fins per inch. Additionally, it used the technique of sine wave fins and rifled copper tubes, which is the secret to great performance and efficiency and gives you an extra 10–20% heat exchanger performance.

- ♨️【SPECIAL PROCESS】Aluminium fins with an epoxy resin coating are used in the fins. It reduces the likelihood of several types of corrosion reactions occurring, offers long-term corrosion protection to increase the unit’s lifespan, and improves performance and dependability.

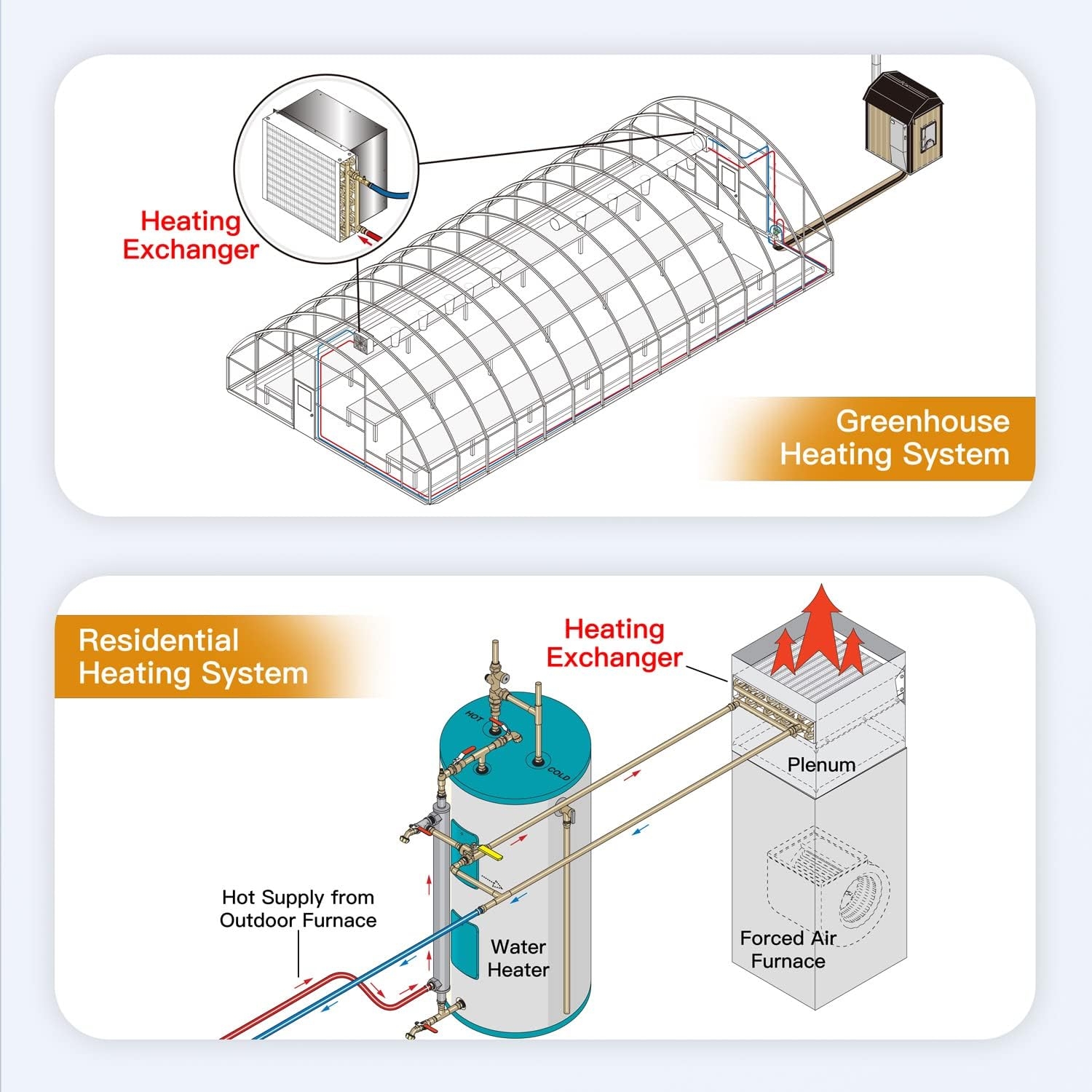

- ♨️【APPLICATION】The Heat Exchanger is ideal for outdoor wood furnaces, greenhouse heating, forced air heating, air conditioning, hybrid systems, and other commercial and domestic heating and cooling needs.

- ♨️【WARRANTY】To ensure a long lifespan and high level of reliability, every Alecoil heat exchanger is put through a helium leak test. Additionally, we offer a 1-year warranty.

- ♨️【NOTICE】Inevitably, the copper tube’s surface oxidizes throughout the manufacturing process, which somewhat affects appearance but has no impact on heat exchanger performance. 12×12″ refers to the effective heat exchanger area, while the maximum outside diameter area is 17.7×12″.