- Edge banding?or?edgebanding?is the name of both a process and an associated narrow strip of material used to create durable and aesthetically pleasing trim edges during finish carpentry. PVC edge banding matches the finish it’s being applied to all veeners.

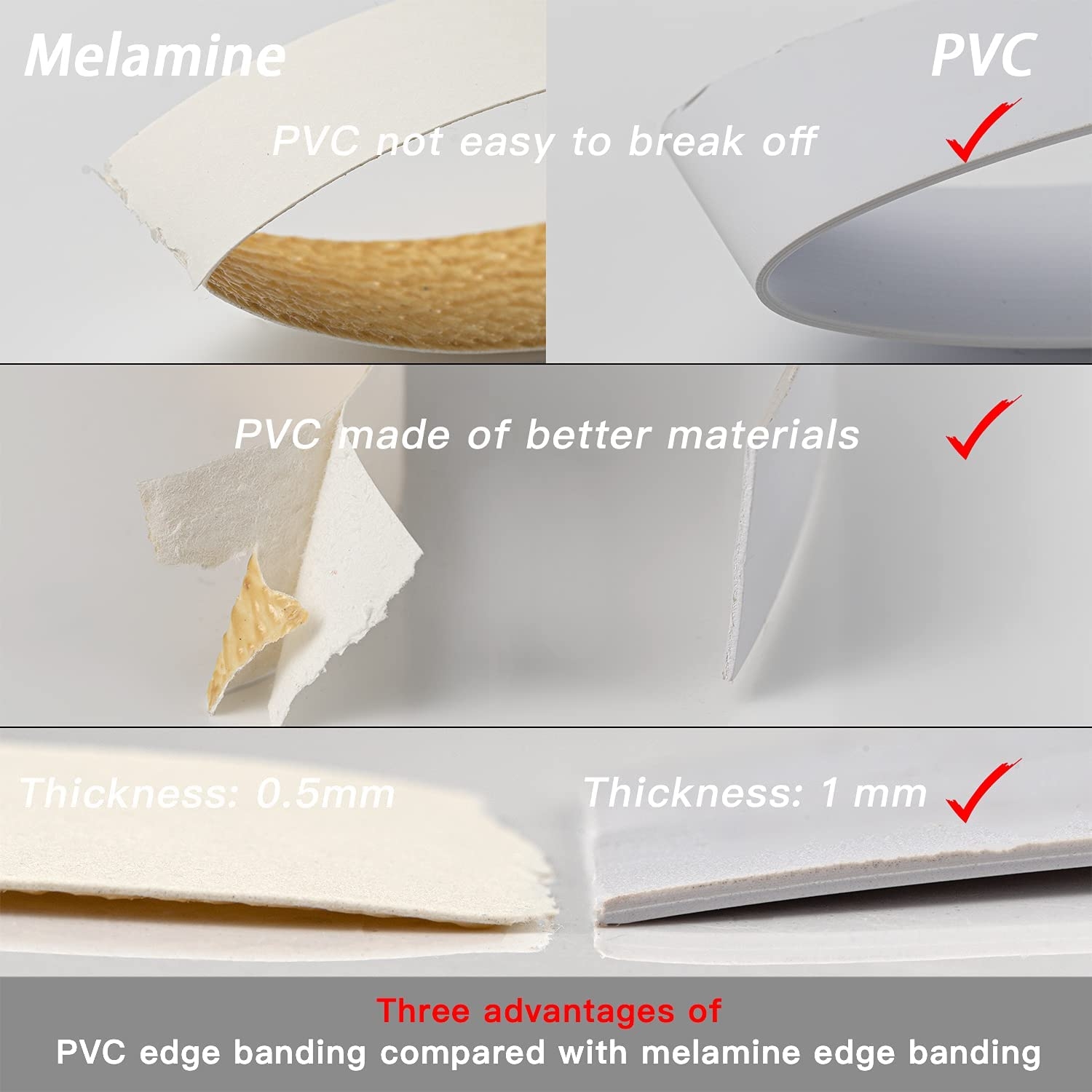

- PVC edge banding?is most popular when using?Pressure Laminated?and?Melamine Cabinets. With modern cabinetry?on the rise, it is not uncommon to see?cabinets with glossy or colorful finishes.?PVC Edge banding?is made from?thermoplastic resin?and is known to be both flexible and durable.

- Edge banding?is mainly done to cover?plywood sides?in order to match a cabinet’s finished look, but it also protects the?inner plywood?from possibly warping. For high-use areas, like?kitchens and bathrooms, 1mm thick edge banding is recommended to better protect your cabinets from frequent use.

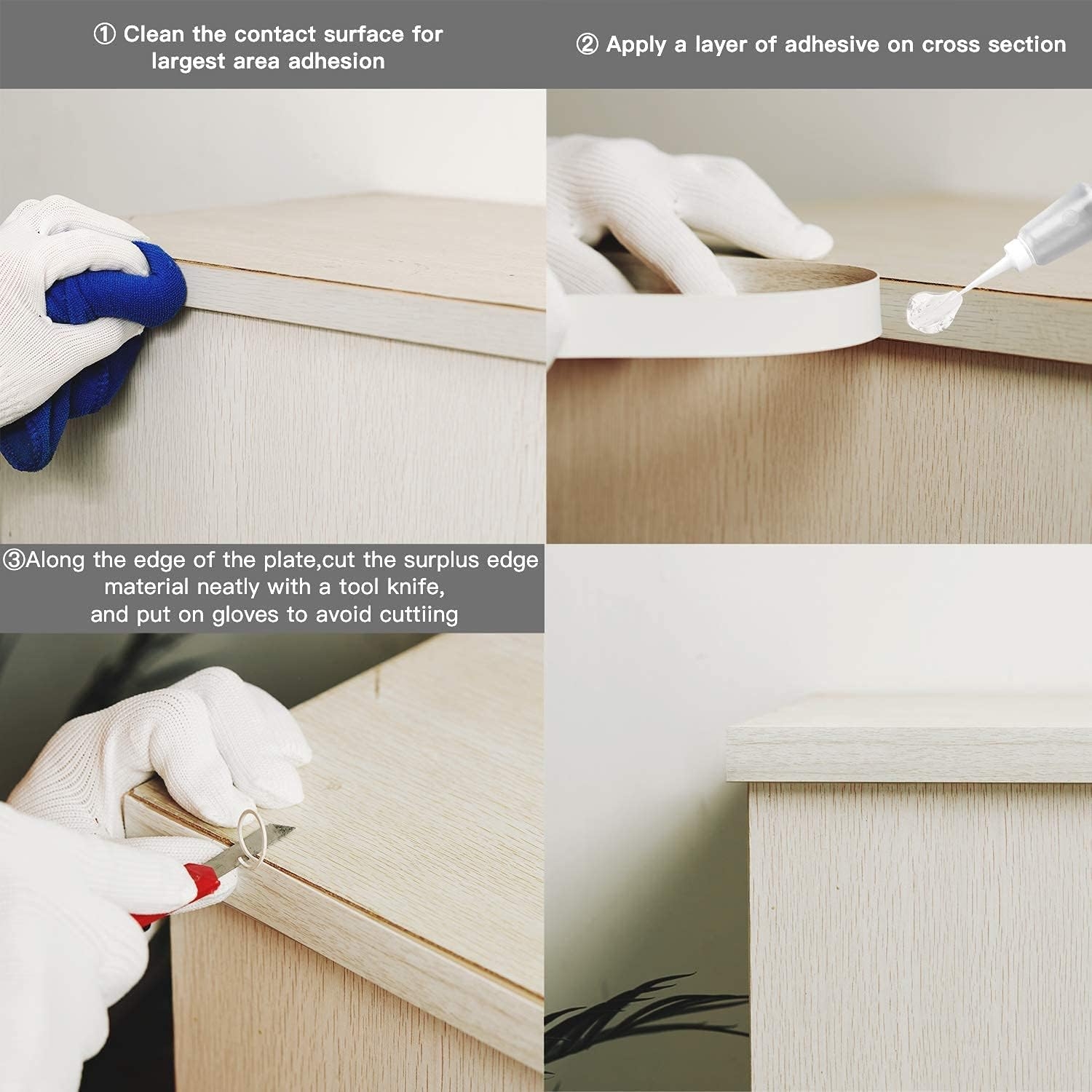

- Edge banding is used to cover the exposed sides of materials such as?plywood,?particle board?or?MDF, increasing durability and giving the appearance of a solid or more valuable material. Because our edge banding is different from other materials, there is no need to use clothes iron or a hot melt gun. You can glue it on with construction adhesive, tacke the ends, and hold it in place with painters tape.

- Because our edge banding is different from other materials, there is no need to use clothes iron or a hot melt gun. You can glue it on with construction adhesive, tacke the ends, and hold it in place with painters tape. Visit our Edgebanding?PVC Color Match-Look Up?to find the PVC color matching edge banding you are looking for. Many sizes to choose from by all major brands including.